When starting a new project, whether it's a large-scale construction effort or a weekend DIY task, choosing the right materials can make all the difference. Among the most versatile and cost-effective options available today are welded wire mesh and square wire mesh. These materials are increasingly favored by professionals and hobbyists alike due to their strength, adaptability, and long-term value. So why exactly are these two types of wire mesh gaining so much attention? Let’s explore what makes them the ideal choice for your next build.

Understanding the Difference: Welded vs. Square Wire Mesh

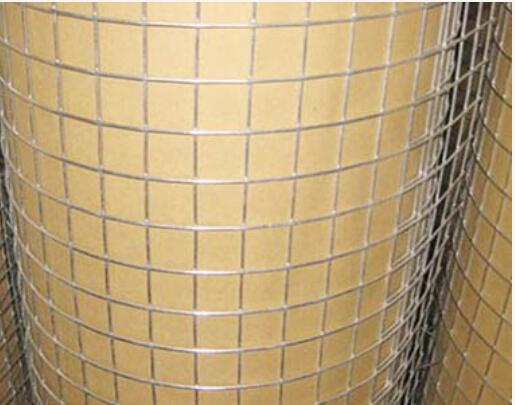

At first glance, welded wire mesh and square wire mesh may appear similar, but they offer distinct structural advantages depending on your needs. Welded wire mesh features wires that are fused together at their intersections through an automated welding process. This results in a highly stable and rigid structure that's ideal for applications requiring strength and uniformity, such as reinforcing concrete or building secure fencing.

On the other hand, square wire mesh typically refers to a grid where the openings are square-shaped, and the wires are either welded or woven. This type of mesh is known for its flexibility and ease of manipulation, making it a popular choice for projects that demand customization, like garden trellises or lightweight storage racks.

Durability That Stands the Test of Time

One of the standout features of both welded and square wire mesh is their impressive durability. Thanks to advanced manufacturing techniques, these materials are engineered to withstand heavy loads, resist corrosion, and maintain their structural integrity even in challenging environments.

In construction projects, welded wire mesh plays a crucial role in reinforcing concrete slabs and walls, preventing cracks and increasing the overall lifespan of the structure. In agricultural settings, square wire mesh provides a lightweight yet strong solution for animal enclosures or garden fencing. Both types are often treated with protective coatings like zinc or PVC to enhance their resistance to rust and environmental wear.

Endless Applications Across Industries

The adaptability of welded and square wire mesh means they’re not limited to just one type of project. In fact, these materials are used across a wide range of industries and applications. In construction, they are essential for creating strong, stable structures. In landscaping and gardening, they serve as trellises, fencing, and even decorative elements. Industrial uses include filtration systems, shelving units, and equipment guards. Even in home environments, these meshes can be transformed into creative DIY solutions like pet enclosures, custom furniture, and wall art.

Their modular nature allows them to be cut, bent, or welded into custom shapes, making them ideal for both large-scale and small-scale applications. Whether you're reinforcing a concrete floor or designing a modern shelving unit, these wire meshes offer unmatched versatility.

Trusted by Professionals and DIY Enthusiasts Alike

From architects and engineers to passionate DIYers, the appeal of welded and square wire mesh is universal. Many professionals choose welded wire mesh for its reliability in structural applications. It’s commonly used in high-rise buildings, bridges, and roadways where safety and performance are paramount.

Meanwhile, DIY users often turn to square wire mesh for its ease of handling and aesthetic potential. Whether it’s crafting a custom headboard or building a backyard chicken coop, this material provides a strong foundation that can be tailored to fit any vision.

Environmentally Friendly and Sustainable

As sustainability becomes a growing concern in construction and design, welded and square wire mesh stand out for their eco-friendly attributes. Both materials are typically made from recyclable metals and can be reused or repurposed at the end of their long lifespans. Their durability also contributes to reduced waste, as they don’t need frequent replacement like some alternative materials.

In green building projects, these wire meshes are valued for their ability to support sustainable practices. They can be integrated into energy-efficient designs, such as ventilation systems or solar panel supports, while still providing structural integrity.

How to Choose the Right Wire Mesh for Your Project

Selecting the right type of wire mesh involves more than just knowing the difference between welded and square varieties. Consider the material—common options include galvanized steel, PVC-coated wire, and stainless steel. Each offers different levels of corrosion resistance and aesthetic appeal.

Pay attention to mesh specifications such as wire diameter and opening size, as these will impact the mesh’s strength and usability. For outdoor or high-moisture environments, opt for anti-rust treatments or coated varieties to ensure longevity.

While it may be tempting to go for the lowest price, investing in high-quality wire mesh will pay off in the long run. Low-cost alternatives may compromise on durability and performance, leading to costly repairs or replacements down the line.

Let Your Creativity Shine with Wire Mesh

Whether you're building a modern balcony railing, crafting a custom bookshelf, or helping your garden plants climb skyward, wire mesh offers a world of creative possibilities. Its combination of strength, flexibility, and visual appeal makes it a standout choice for both functional and decorative applications.

So why not start your next project with welded wire mesh or square wire mesh? With the right tools and a bit of imagination, you’ll be amazed at what you can create. Whether you're a seasoned builder or a first-time DIYer, these materials provide the perfect foundation for bringing your ideas to life.