The Art of Grid Structures: Starting from the Basics

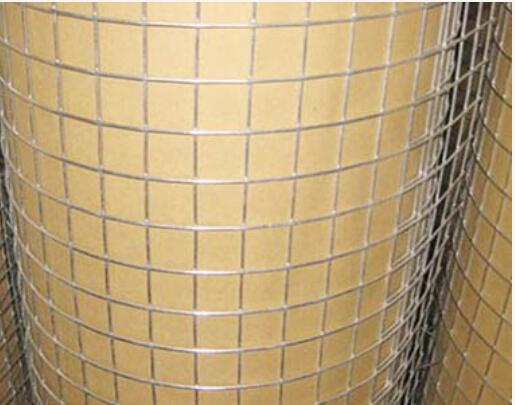

At first glance, welded wire mesh and square wire mesh may appear similar, but their structural differences significantly influence their performance and suitability for various applications. Welded wire mesh features wires that are electrically fused at their intersections, creating a rigid and uniform grid. In contrast, square wire mesh typically consists of woven wires that form consistent square openings, offering flexibility in design and application. Understanding the manufacturing processes behind each type reveals how these materials achieve their unique mechanical properties and adaptability in different environments.

The Secret Weapon on Construction Sites: Wide-Ranging Applications

These wire mesh types have become indispensable in the construction industry, particularly as reinforcement for concrete structures. Their ability to enhance tensile strength and prevent cracking makes them ideal for driveways, patios, and walls. Beyond structural use, they also serve as practical solutions for fencing, partitioning, and temporary supports on job sites. Engineers carefully consider factors like mesh aperture size and wire thickness to ensure optimal load distribution and durability, tailoring each selection to the specific demands of the project.

DIY Enthusiast’s Dream Material: From Imagination to Reality

For those who enjoy hands-on projects, both welded and square wire mesh offer a wealth of creative potential. Homeowners and crafters have transformed these materials into stylish furniture pieces, decorative room dividers, and even plant trellises. In gardens, they provide sturdy support for climbing plants and effective barriers for small animals. Their adaptability to cutting, bending, and painting makes them a favorite among DIYers who seek both functionality and aesthetic appeal in their creations.

The Science Behind Durability: Built to Last

The strength of these wire mesh types lies not only in their structure but also in their resistance to wear and environmental stress. Both materials can be treated with galvanization or protective coatings to resist rust and corrosion, ensuring longevity even in harsh climates. Their high tensile strength and resistance to deformation make them suitable for long-term installations, from industrial flooring to outdoor enclosures. With proper maintenance, these mesh types can serve reliably for years, offering a cost-effective solution to many construction and design challenges.

Eco-Friendly and Sustainable: A Green Choice for Modern Projects

In an era increasingly focused on sustainability, welded and square wire mesh stand out as environmentally responsible materials. Often made from recyclable steel or iron, they contribute to reduced material waste and energy consumption during production. Their use in green building initiatives, such as LEED-certified structures, further highlights their role in sustainable design. By choosing wire mesh, project planners can align their material selections with eco-conscious goals while maintaining structural integrity and visual appeal.

Pushing the Boundaries: Innovative Uses on the Horizon

As technology and design evolve, so too do the applications for wire mesh. Artists and architects are exploring the use of these materials in public installations and urban landscapes, appreciating their visual texture and strength. In the realm of advanced manufacturing, wire mesh is being tested in 3D-printed building components and modular construction systems. Industry experts predict even more groundbreaking uses in the future, including smart infrastructure and adaptive building skins that respond to environmental changes.

Making the Right Choice: Matching Material to Mission

Selecting the right type of wire mesh requires careful consideration of several key factors. The intended application, load requirements, exposure to elements, and aesthetic preferences all play a role in the decision-making process. While welded mesh is often preferred for heavy-duty reinforcement, square mesh may be more suitable for decorative or lightweight applications. Avoiding common misconceptions, such as equating thickness with strength alone, ensures a more informed and successful material selection. Balancing budget constraints with long-term performance is also essential to achieving the best outcome.

Inspiration from Real-World Success: Case Studies That Shine

Across the globe, numerous projects have demonstrated the effectiveness of welded and square wire mesh in real-world scenarios. From modern residential developments that incorporate mesh into facades and interior design elements to large-scale infrastructure projects that rely on its strength for safety and stability, the results speak for themselves. These success stories highlight the seamless integration of function and form, proving that wire mesh is more than just a construction material—it's a design solution that continues to inspire innovation and excellence.