In the vast world of construction materials, few components are as versatile and widely used as wire mesh. From reinforcing concrete to supporting crops in greenhouses, wire mesh plays a crucial role in countless industries. Among the many types available, two stand out for their durability and adaptability: welded wire mesh and square wire mesh.

The Grid That Binds Us

Wire mesh is more than just a grid of metal wires—it’s a foundational element in modern engineering and design. Whether you're building a residential fence or reinforcing the framework of a skyscraper, choosing the right type of mesh can make all the difference. Welded wire mesh and square wire mesh each bring unique strengths to the table, making them ideal for specific applications.

What Exactly Is Welded Wire Mesh?

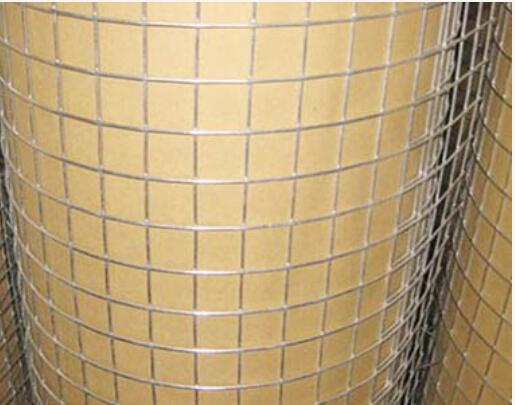

Welded wire mesh is constructed by electrically fusing intersecting wires at their contact points, creating a rigid and stable structure. This process ensures that each joint is strong and resistant to displacement, making the mesh particularly suitable for applications that demand structural integrity. It is commonly used in concrete reinforcement, fencing, and industrial screening systems where a fixed, non-flexing grid is required.

Square Wire Mesh: A Shape That Speaks Volumes

Square wire mesh, on the other hand, is typically woven rather than welded. This means the wires are interlocked in a crisscross pattern without being fused, allowing for a bit more flexibility. Its uniform square openings make it ideal for applications like sieving, filtration, and decorative paneling. In agricultural settings, it’s often used for fencing small animals or supporting climbing plants due to its open, regular pattern.

Battle of the Bonds: Spot-Welded vs. Woven

One of the most significant differences between these two types of mesh lies in how the wires are connected. Welded mesh offers superior rigidity and resistance to deformation, especially under heavy loads. Woven square mesh, while less rigid, provides greater flexibility and can absorb minor impacts without breaking. This makes it a preferred option in environments where some movement is expected, such as vibration-prone machinery or outdoor enclosures exposed to wind.

Strength in Structure: Which Mesh Holds Up Better?

When it comes to mechanical strength, welded wire mesh generally outperforms square wire mesh. Its spot-welded joints create a stronger bond that resists both tension and shear forces, making it ideal for use in structural applications like bridge decks and retaining walls. Square mesh, while not as robust in high-stress scenarios, still offers excellent durability in less demanding environments like garden trellises or light-duty enclosures.

Where They Shine: Industry by Industry

Welded wire mesh is the go-to choice in construction, especially for reinforcing concrete slabs and foundations. Its uniform structure ensures even load distribution and prevents cracking. In contrast, square wire mesh finds its niche in agriculture, mining, and food processing industries, where its open weave is perfect for separating materials or supporting plant growth. For decorative purposes, square mesh also lends itself well to architectural finishes and fencing with aesthetic appeal.

Cost, Customization, and Convenience

When budget is a concern, square wire mesh often comes out on top due to its simpler manufacturing process. However, welded mesh offers greater longevity in heavy-duty applications, potentially reducing long-term costs. Both types can be customized in terms of wire thickness and mesh size, but welded mesh tends to be more rigid in its specifications once produced. Installation-wise, welded mesh is generally easier to handle due to its rigid form, while woven square mesh may require additional support structures to maintain shape.

Behind the Scenes: Manufacturing and Material Choices

Both types of mesh can be made from a variety of materials, including galvanized steel, stainless steel, and PVC-coated wire. Galvanized options offer excellent corrosion resistance, making them ideal for outdoor use. The manufacturing method—whether spot welding or weaving—also affects the final product's performance. Welded mesh tends to be more consistent in shape and strength, while woven mesh allows for more design flexibility.

The Green Factor: Eco-Friendly and Reusable Options

As sustainability becomes increasingly important, both mesh types offer eco-friendly benefits. Made from recyclable metals, they can be repurposed at the end of their lifecycle. Square mesh, with its simpler structure, is often easier to dismantle and reuse, while welded mesh’s durability means it can serve for decades without replacement. Choosing a mesh that matches your project’s lifespan and environmental impact goals can make a significant difference.

When to Call It: Making the Final Call

Deciding between welded wire mesh and square wire mesh ultimately comes down to the specific needs of your project. Ask yourself: Is structural strength the top priority, or do you need a more flexible, customizable solution? Will the mesh be exposed to extreme weather or constant movement? How important is aesthetic appeal or environmental impact? By answering these questions, you’ll be well on your way to selecting the right mesh for your needs.

Real-World Stories: Projects That Got It Right

Across the globe, construction teams and designers have successfully implemented both types of mesh to great effect. A recent bridge rehabilitation project in Europe utilized welded wire mesh to reinforce the concrete deck, ensuring decades of durability under heavy traffic. Meanwhile, an organic farm in the U.S. opted for square wire mesh to support trellises for climbing vegetables, allowing for optimal airflow and easy harvesting. These real-world examples highlight how choosing the right mesh can lead to long-term success and satisfaction.