In today’s world of engineering and design, materials must be as adaptable as they are strong. Among the most versatile and enduring choices are welded wire mesh and square wire mesh. These materials are not just structural essentials — they are integral components across industries, from construction to agriculture, and from industrial manufacturing to residential design. In this article, we delve into the many applications and advantages of these two wire mesh types, highlighting why they are trusted solutions for a wide range of needs.

Building the Backbone of Modern Infrastructure

When it comes to large-scale construction and infrastructure development, few materials offer the reliability and strength that welded and square wire meshes provide. These meshes are extensively used in reinforcing concrete structures, ensuring enhanced tensile strength and long-term durability. In applications such as wall reinforcement and flooring systems, they help prevent cracking and improve load distribution. Their use in fencing and perimeter security also makes them a go-to solution for both residential and commercial projects. The ease of installation and high tensile strength make them a preferred choice for contractors aiming to deliver robust and efficient builds.

Industrial Strength Meets Everyday Use

Industrial environments demand materials that can withstand heavy use, pressure, and exposure to harsh conditions. Welded wire mesh and square wire mesh excel in these scenarios due to their superior structural integrity and resistance to wear and tear. Whether used in heavy-duty shelving units, protective guards for machinery, or ventilation duct systems, these meshes provide a balance of strength and breathability. Their ability to endure high-stress conditions without deformation ensures that they remain functional over extended periods, contributing to safer and more efficient industrial operations.

From Gardens to Greenhouses: The Natural Side of Wire Mesh

Beyond the industrial and construction sectors, wire mesh plays a crucial role in agriculture and horticulture. Gardeners and farmers often use these materials to create plant supports, animal enclosures, and greenhouse frameworks. The open structure of the mesh allows for optimal air circulation, promoting healthy plant growth while keeping pests at bay. Additionally, both welded and square wire meshes are highly durable and reusable, making them an environmentally friendly option for sustainable farming practices. Their resistance to corrosion further ensures that they can withstand exposure to soil, moisture, and outdoor elements.

Design Meets Function: Residential Uses You Didn’t Expect

Homeowners and interior designers are increasingly turning to wire mesh for its unique combination of functionality and aesthetic appeal. From decorative room dividers to custom light fixtures and pet enclosures, these materials offer creative and durable solutions for modern living spaces. Their metallic finish can complement both rustic and contemporary interiors, while their adaptability allows for seamless integration into DIY projects. Whether used as a stylish wall feature or a practical solution for pet containment, wire mesh proves that utility and beauty can coexist.

What Sets Welded and Square Mesh Apart?

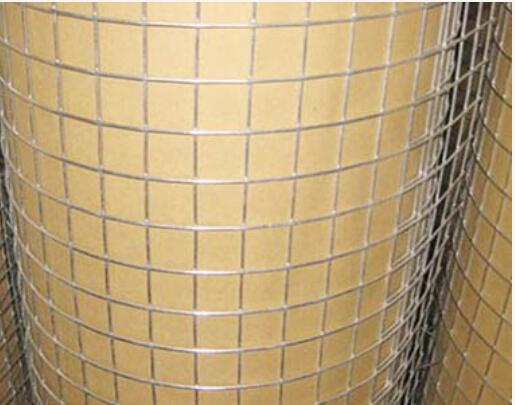

While both welded and square wire meshes offer durability and versatility, they differ in their manufacturing processes and structural characteristics. Welded wire mesh is typically produced by electrically fusing intersecting wires at their contact points, creating a rigid and uniform grid. This method ensures a strong, stable structure ideal for applications requiring consistent spacing and high tensile strength. Square wire mesh, on the other hand, is often woven or welded to form a grid with equally sized openings, providing a balance between flexibility and firmness. Choosing the right type depends on the specific requirements of the project — whether it's the need for structural rigidity, adaptability, or ease of customization.

Testing the Limits: Why These Meshes Last Longer

Durability is a defining feature of both welded and square wire meshes. To ensure longevity, these materials are often treated with protective coatings such as galvanization or PVC. Galvanized wire mesh is resistant to rust and corrosion, making it suitable for outdoor and high-moisture environments. PVC-coated variants offer an additional layer of protection while also providing a smooth, visually appealing finish. These treatments significantly extend the lifespan of the mesh, allowing it to perform reliably under challenging conditions without frequent replacement.

Customization and Beyond: Tailoring Mesh to Your Needs

One of the greatest advantages of welded and square wire meshes is their adaptability. Manufacturers can customize these products to meet specific size, wire thickness, mesh aperture, and coating color requirements. This flexibility is particularly valuable for industries with unique demands, such as architectural design, specialized agriculture, or bespoke furniture making. As the need for tailored solutions continues to grow, suppliers are increasingly offering rapid production and delivery options to meet diverse project timelines and specifications.

A Global Perspective: Where and How These Meshes Are Used Around the World

The global demand for welded and square wire mesh reflects their universal utility. In Europe, they are widely used in highway infrastructure and architectural facades. In Asia, they support agricultural expansion and urban development projects. In North and South America, they contribute to everything from industrial manufacturing to residential safety systems. Their adaptability to varying climatic and regulatory standards ensures that they remain a trusted resource across continents, proving that no matter where you are, these meshes can be tailored to suit local needs while maintaining high performance and quality.