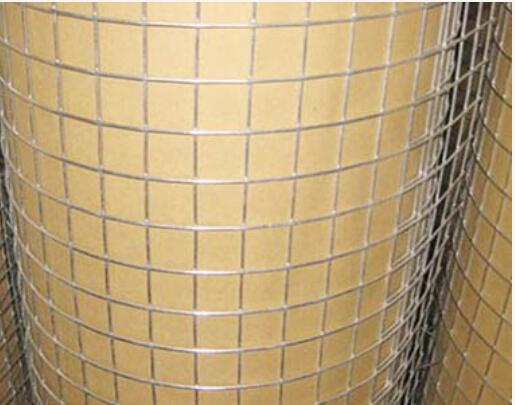

Welded wire mesh in action at a construction site

From Construction Sites to Garden Beds: The Many Faces of Wire Mesh

Walk through any modern city, and you’ll see the invisible hand of wire mesh shaping its infrastructure. In construction, it reinforces concrete structures, enhances wall stability, and supports formwork. In agriculture, it forms the backbone of animal enclosures and crop protection systems. Even in urban design, it plays a role in decorative fencing and green wall installations. These materials are not just functional — they're foundational.

Consider a homeowner building a chicken coop or a community garden installing a new fence. Both scenarios benefit from the strength and adaptability of wire mesh. It provides security, durability, and a clean finish that blends well with both modern and rustic aesthetics.

Precision in every weld: The manufacturing process

The Science Behind the Strength

The durability of welded and square wire mesh begins with the materials and processes used to create them. Most wire mesh products are made from low-carbon steel, galvanized steel, or stainless steel, each offering different levels of corrosion resistance and structural integrity. The welding process ensures that each intersection is fused securely, while square mesh typically features crimped wires that lock into place.

The result is a product that resists deformation, supports heavy loads, and withstands environmental stressors like moisture and temperature fluctuations. Whether it's buried underground or exposed to the elements, wire mesh maintains its form and function over time.

Comparing welded and square wire mesh structures

Welded vs Square: Choosing the Right Fit

While both welded and square wire mesh serve similar purposes, their construction methods lead to distinct advantages. Welded wire mesh offers superior rigidity and is ideal for applications requiring precise load distribution, such as concrete reinforcement. Square wire mesh, with its crimped cross points, is often more flexible and cost-effective, making it a popular choice for fencing and light-duty DIY projects.

For large-scale construction, welded mesh provides the structural consistency needed to meet engineering standards. For temporary installations or garden use, square mesh might be the more practical option due to its ease of handling and lower cost.

Wire mesh used for fencing and boundary control

Building with Confidence: The Role in Modern Construction

Engineers and builders rely on wire mesh to enhance the safety and longevity of structures. When embedded in concrete, it helps control cracking and distributes stress evenly. In wall systems, it acts as a substrate for plaster or stucco, improving adhesion and reducing the risk of surface failure.

From high-rise buildings to highway barriers, wire mesh is a critical component that ensures structures meet safety codes and perform under pressure. Its use is not just a best practice — it's often a regulatory requirement in modern construction.

Secure Your Space: Fencing and Safety Applications

Wire mesh is a top choice for fencing due to its strength, visibility, and ease of installation. Whether used for perimeter security, animal enclosures, or temporary site fencing, it offers a balance of durability and adaptability. Galvanized and coated options provide added protection against rust and corrosion, making them suitable for both urban and rural environments.

Maintenance is minimal, and replacement is straightforward if damage occurs. This makes wire mesh an economical long-term solution for both commercial and residential fencing needs.

DIY and Beyond: Creative Uses in the Home and Garden

Beyond industrial applications, wire mesh opens up a world of creative possibilities for homeowners and DIY enthusiasts. It can be shaped into garden trellises, bird cages, storage shelves, and even decorative wall art. Its modular nature allows for easy customization and integration into existing structures.

For those looking to personalize their outdoor space, wire mesh offers a blank canvas. With a little creativity and basic tools, it can be transformed into a unique feature that adds both function and flair.

Green Building and Sustainability

In the push for greener construction practices, wire mesh plays a valuable role. Made from recyclable metals, it contributes to sustainable building materials and reduces environmental impact. It's commonly used in green roofs to support plant growth, in erosion control systems, and as part of permeable pavement designs that manage stormwater runoff.

As architects and builders seek to meet sustainability standards like LEED certification, wire mesh offers a reliable, eco-friendly solution that aligns with modern environmental goals.

Choosing the Right Mesh for Your Project

Selecting the right wire mesh involves understanding your project’s specific requirements. Key factors include mesh size, wire diameter, and material type. Smaller mesh openings offer greater strength and are ideal for structural reinforcement, while larger openings may be better suited for fencing or decorative use.

When sourcing wire mesh, always verify the supplier's credentials and inspect sample materials to ensure quality. Look for consistent weld points, uniform spacing, and appropriate coatings for the intended environment.

The Future of Wire Mesh: Smarter, Stronger, More Versatile

As construction and design evolve, so too does the role of wire mesh. In modular and prefabricated building systems, it provides the reinforcement needed for rapid assembly. In 3D-printed walls and smart homes, it integrates with sensors and security systems to support next-generation infrastructure.

With advancements in materials science and manufacturing, we can expect to see even more specialized wire mesh products tailored for specific applications — from seismic-resistant structures to interactive building facades.