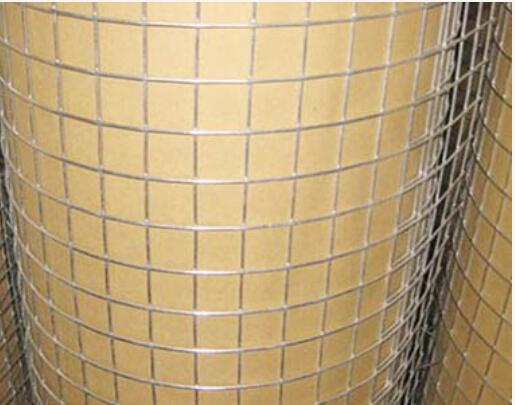

When it comes to materials that stand the test of time, few can rival the resilience and adaptability of metal mesh. Among the many varieties available, welded wire mesh and square wire mesh have emerged as go-to solutions for industries that demand strength, precision, and longevity. Whether you're constructing a high-rise building or reinforcing a chicken coop, these two types of wire mesh offer unmatched durability and performance.

When Strength Meets Precision: How Wire Mesh Redefines Modern Engineering

The evolution of wire mesh has mirrored the progress of modern engineering itself. From rudimentary fencing to advanced structural reinforcements, wire mesh has quietly become a cornerstone of industrial design. Welded wire mesh, with its strong, fused intersections, and square wire mesh, known for its uniform grid pattern, are both engineered to perform under pressure. These materials are not just components—they are integral elements that provide structural integrity and precision in applications ranging from architectural design to agricultural enclosures.

Engineers, architects, and manufacturers favor these materials for their ability to blend strength with flexibility. Whether it's supporting concrete structures or forming the skeleton of a secure boundary, the right wire mesh can make all the difference in performance and longevity.

From Farms to Cities: A Versatile Material with Endless Applications

The versatility of welded and square wire mesh is perhaps their most compelling feature. In agriculture, they serve as durable fencing for livestock, enclosures for poultry, and support structures for barns and storage facilities. In the construction industry, these meshes reinforce concrete slabs, provide support for drywall systems, and offer safe, secure barriers on job sites. Industrial manufacturing relies on them for filtration systems, protective guards for machinery, and even conveyor belt frameworks.

Security is another domain where these materials shine. High-security facilities, prisons, and border control installations depend on the strength and visibility of wire mesh to maintain safety without compromising aesthetics. Beyond traditional uses, creative minds have found innovative ways to incorporate wire mesh into DIY furniture, garden designs, and even temporary art installations, proving that functionality and form can coexist.

Welded vs. Square: Understanding the Structural Differences and Performance Benefits

While both types of mesh offer durability, their structural differences determine where each excels. Welded wire mesh features strong, electrically fused joints that create a rigid and load-bearing framework. This makes it ideal for applications where weight distribution and structural support are critical—such as in reinforced concrete or fencing that must withstand harsh weather conditions.

On the other hand, square wire mesh is characterized by its uniform openings, which allow for even force distribution across the surface. This consistency makes it particularly suitable for tasks like filtration, screening, or any application where material flow or pressure must be evenly managed. The choice between the two often comes down to the specific requirements of the project, such as load-bearing capacity, flexibility, and installation ease.

Material selection also plays a crucial role. Galvanized steel offers corrosion resistance, stainless steel provides superior durability in aggressive environments, and PVC-coated options add an extra layer of protection while enhancing visual appeal.

The Secret to Longevity: Why These Meshes Stand the Test of Time

What sets these wire meshes apart is their ability to endure. Anti-corrosion treatments such as galvanization or powder coating significantly extend their lifespan, even in humid or chemically aggressive environments. Their high tensile and shear strength ensure that they remain intact under pressure, while their resistance to warping and deformation maintains structural integrity over time.

Whether facing extreme weather, constant mechanical stress, or heavy use, these meshes maintain their performance with minimal maintenance. This low upkeep and high durability translate into long-term cost savings, making them a smart investment for both large-scale and personal projects.

Trusted by Professionals: Real-World Endorsements from Around the Globe

Across industries, professionals rely on these wire mesh types for their consistent performance. Architects and builders cite the ease of integration with modern construction methods, while farmers appreciate the long-lasting nature of their enclosures. Security experts confirm that high-security installations benefit from the visibility and strength these meshes provide.

Real-world examples abound. A recent infrastructure project saw welding mesh reduce installation time by 30% while improving structural cohesion. Even when budgets are tight, professionals opt for high-quality wire mesh, understanding that the upfront cost is far outweighed by the long-term value. Certifications and adherence to international standards further assure users of their reliability and safety.

Looking Ahead: The Future of Wire Mesh Innovation

As industries evolve, so too does the technology behind wire mesh. Sustainable manufacturing practices are gaining traction, with eco-friendly production methods reducing environmental impact. Smart mesh systems are emerging, integrating with sensors and surveillance to create intelligent fencing and monitoring solutions.

New material combinations, such as carbon fiber and composite integration, are pushing the boundaries of performance. Meanwhile, 3D printing is opening up new design possibilities, allowing for custom patterns and structures tailored to specific needs. The future of wire mesh is not just durable—it’s intelligent, sustainable, and adaptable.

Choosing the Right Mesh for Your Project: A Practical Guide

Selecting the ideal mesh for your application starts with understanding your needs. Is the mesh meant for structural support, fencing, filtration, or decorative purposes? The answer will guide your choice between welded and square options. Consider the environment—will the mesh be exposed to moisture, chemicals, or UV radiation? This will influence your material selection, from galvanized steel to PVC-coated variants.

Mesh specifications such as aperture size, wire thickness, and roll dimensions also play a crucial role in performance. Installation method and expected maintenance should not be overlooked. Finally, sourcing from a reputable supplier ensures quality, consistency, and compliance with safety standards.

More Than Material: A Solution That Builds Confidence

At its core, wire mesh is more than just a product—it's a solution. Whether you're reinforcing a building, securing a facility, or crafting a custom design, the right mesh can save time, reduce costs, and enhance safety. As industries continue to evolve, these materials remain a constant—offering reliability, adaptability, and performance in a world that demands more from every component.

Welded wire mesh and square wire mesh aren’t just durable; they’re dependable. In a fast-changing market, that kind of stability is invaluable.