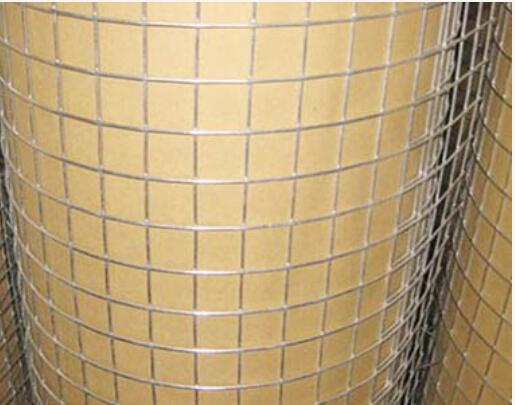

Durable Welded Wire Mesh and Square Wire Mesh for Industrial & Home Use

When it comes to selecting materials that offer both strength and adaptability, few products rival the performance of welded wire mesh and square wire mesh. Whether you're reinforcing concrete in a construction project or crafting a custom shelving unit for your living room, these versatile grids deliver the durability and flexibility needed to tackle a wide range of tasks. In this article, we’ll explore the features, benefits, and creative applications of these two essential materials that are trusted across industries and households alike.

From Factory Floors to Garden Beds: A Mesh for Every Mission

At first glance, welded wire mesh and square wire mesh may seem interchangeable, but their structural differences make each uniquely suited for specific applications. Welded wire mesh is constructed by fusing intersecting wires at high temperatures, creating a rigid and uniform structure ideal for heavy-duty environments. Square wire mesh, on the other hand, features a consistent square grid pattern that offers both aesthetic appeal and structural integrity, making it popular in both decorative and functional settings.

From agricultural fencing to modern interior design, these wire mesh types are integral in settings as diverse as construction sites, nurseries, and DIY workshops. Whether you're looking to reinforce concrete or build a custom room divider, there's a mesh tailored for your needs.

Why Strength Matters: The Science Behind a Sturdy Wire Mesh

The superior strength of welded wire mesh comes from its manufacturing process. Unlike traditional woven wire mesh, which relies on friction to hold intersections together, welding ensures each joint is permanently fused. This significantly enhances load-bearing capabilities and resistance to deformation under pressure.

Square wire mesh benefits from its geometric design, distributing force evenly across its surface. This makes it especially useful in applications where uniform stress is expected, such as in concrete reinforcement or garden trellises. When compared to standard woven mesh, both welded and square wire options demonstrate superior resilience, especially in dynamic environments where movement and vibration are common.

Built to Last: How Long Can You Expect Your Wire Mesh to Perform?

The longevity of wire mesh depends on several factors: material composition, surface treatment, and environmental exposure. Galvanized steel and stainless steel options offer excellent corrosion resistance, making them ideal for outdoor or high-moisture environments. For those seeking a more aesthetic finish, powder-coated wire mesh provides both durability and a sleek appearance.

Many users report that their welded wire mesh installations remain intact for over a decade with minimal maintenance. In contrast, untreated or poorly installed mesh can degrade within just a few years. Proper installation, such as ensuring adequate drainage and using protective coatings, can significantly extend the lifespan of your mesh.

Beyond Fencing: Unexpected Uses of Wire Mesh at Home

While fencing and construction are common uses, the creative potential of welded wire mesh and square wire mesh extends far beyond industrial applications. In modern homes, these materials are being repurposed into stylish and functional décor elements. Imagine a minimalist room divider made from square wire mesh, allowing light to flow while defining spaces elegantly.

DIY enthusiasts also appreciate the material for crafting custom storage solutions. A lightweight yet sturdy shelving unit built with wire mesh panels can be both practical and visually appealing. In the garden, homeowners have found that mesh-lined planters protect against pests like rodents, while still allowing for proper air circulation and drainage.

In the Field: Real-World Applications That Depend on Wire Mesh

Across industries, welded wire mesh plays a vital role in agriculture, construction, and manufacturing. In farming, it's used for livestock enclosures, seedling trays, and feed bins. Its strength and ease of installation make it a favorite for creating durable, long-lasting structures in rural settings.

In the construction industry, wire mesh is often embedded in concrete to reinforce structures, increasing their tensile strength. It also serves as a protective barrier on scaffolding, ensuring safety during high-rise building projects. Meanwhile, in factories, mesh panels are used to create equipment guards and storage racks, helping to organize spaces while maintaining visibility and airflow.

Choosing the Right Fit: Size, Shape, and Strength for Your Project

Selecting the right mesh for your application involves considering the size of the openings (aperture), the thickness of the wire (wire gauge), and the type of material. For heavy-duty applications like concrete reinforcement, a thicker gauge with larger apertures may be preferable. For delicate applications like screening or decorative use, a finer mesh with smaller openings is ideal.

When deciding between welded wire mesh and square wire mesh, consider the level of rigidity required. Welded mesh is typically more rigid and stable, while square mesh may offer more flexibility depending on the design. Surface treatments like galvanization or PVC coating can also affect the mesh’s suitability for different environments.

A Material That Works Harder: Why This Mesh is Worth the Investment

While cheaper alternatives may offer short-term savings, they often lead to higher maintenance and replacement costs over time. High-quality welded wire mesh and square wire mesh provide a long-term solution that pays dividends in durability and performance. Their resistance to wear and environmental stress ensures that your investment continues to deliver value for years to come.

Moreover, the reusability and recyclability of metal mesh make it an environmentally responsible choice. Whether used in construction, agriculture, or home décor, these materials contribute to sustainable practices by reducing waste and resource consumption.

Final Thoughts

In a world where versatility and durability are key, welded wire mesh and square wire mesh stand out as essential materials for both industrial professionals and DIY enthusiasts. From structural reinforcement to creative home projects, these products offer unmatched strength and adaptability. Choosing the right mesh for your application not only ensures optimal performance but also represents a smart, long-term investment in quality and sustainability.