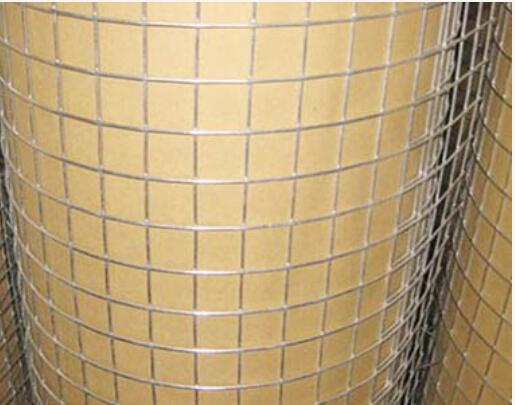

Welded Wire Mesh vs Square Wire Mesh: Uses, Benefits & Applications Explained

In the world of industrial materials, few components are as quietly transformative as metal wire mesh. From towering skyscrapers to quiet rural farms, these grids of steel form the unseen backbone of modern infrastructure. Yet not all meshes are created equal. At the heart of countless engineering decisions lies a subtle but critical choice: welded wire mesh or square wire mesh? While they may appear similar at first glance, their differences shape everything from structural integrity to aesthetic expression.

When Steel Meets Spark: The Birth of Structural Integrity

The moment electricity surges through intersecting steel wires, fusing them into precise junctions, something remarkable happens—welded wire mesh is born. This isn’t just assembly; it’s metallurgical alchemy. Each weld acts like a tiny anchor, locking wires in place with unwavering rigidity. Unlike woven alternatives that rely on tension, this fusion creates a monolithic grid capable of resisting shear forces and maintaining alignment under heavy loads.

This inherent stability makes welded wire mesh indispensable in reinforced concrete applications. Whether forming the skeleton of retaining walls, floor slabs, or bridge decks, it ensures even load distribution and minimizes cracking over time. Contractors value its predictability—no shifting during pouring, no manual tying required. In fast-paced urban developments, where time equals cost, this efficiency translates into real-world savings and safer structures.

Square Grids, Infinite Possibilities: Beyond Geometric Perfection

Square wire mesh embodies order—a lattice of uniform openings defined by exact right angles. But beneath its clean geometry lies functional brilliance. Because each aperture is identical, stress spreads evenly across the entire surface, reducing weak points and enhancing resistance to deformation. This consistency is crucial in applications demanding precision, such as sieving systems in mining or grain processing plants, where particle size must be strictly controlled.

On farms, square mesh offers both security and visibility. Farmers can monitor herds without obstruction while preventing animal escapes. Its open structure also allows light and air to pass through, making it ideal for ventilation grilles, equipment guards, and even sound-diffusing panels in industrial buildings. There's a quiet elegance in its repetition—a visual rhythm that architects increasingly embrace not just for utility, but for design.

The Science of Longevity: How These Meshes Defy Time and Elements

Durability isn’t accidental—it’s engineered. Both welded and square wire meshes often feature galvanized coatings, where a layer of zinc shields the underlying steel from corrosion. However, their performance diverges in extreme conditions. Welded mesh, with its fused joints, resists unraveling even when bent or subjected to vibration. In coastal regions or areas with high salinity, this resilience prevents premature degradation caused by saltwater exposure.

Square mesh, especially when cold-drawn and tightly calibrated, exhibits superior fatigue resistance in cyclic loading environments—think conveyor belts or vibrating screens. When combined with advanced polymer coatings or stainless steel alloys, both types gain extended lifespans, surviving decades in harsh climates. For projects built to last—from earthquake-resistant foundations to offshore aquaculture pens—material longevity isn't optional; it's foundational.

Invisible Frameworks of Modern Life

Walk through any major city, and you're surrounded by evidence of welded wire mesh. It’s embedded in tunnel linings, elevator shafts, and platform edges of subway stations—silent protectors ensuring public safety. During one retrofit project in a seismic zone, engineers credited prefabricated welded panels with cutting installation time by 40%, allowing rapid reinforcement of aging infrastructure without disrupting transit.

Meanwhile, square mesh finds purpose in flexible solutions—temporary barriers at events, modular storage units in warehouses, or protective covers for machinery. Its adaptability spans sectors, proving that simplicity, when well-executed, becomes versatility.

Design Reimagined: Where Engineering Meets Aesthetics

Today’s designers see more than function in wire mesh—they see potential. Architects incorporate both welded and square variants into building facades, creating dynamic shadows and diffused lighting effects. Interior spaces use layered mesh partitions to define zones without blocking airflow or sightlines. Art installations leverage its modularity, bending and stacking grids into intricate sculptures that respond to wind and light.

This crossover from utility to artistry highlights a broader shift: materials once hidden within structures now take center stage, celebrated for their honesty and industrial beauty.

Making the Right Choice: Context Is Everything

Selecting between welded and square wire mesh depends on context. Near oceanic environments, welded galvanized mesh withstands corrosive sprays better due to joint integrity. In agricultural fencing, square mesh provides optimal balance between visibility and containment. For temporary construction barriers, ease of customization favors welded panels. In precision filtration systems, square mesh’s uniformity ensures consistent results.

Understanding the environment, load requirements, and lifecycle expectations transforms selection from guesswork into strategy.

The Future Woven in Innovation

Looking ahead, the evolution continues. Smart coatings capable of self-repairing micro-scratches are entering testing phases. Recycled steel content is rising, aligning production with circular economy goals. Researchers explore embedding sensors within mesh layers for structural health monitoring—turning passive materials into intelligent systems.

As sustainability drives innovation, today’s wire mesh won’t just support buildings—it will help build a smarter, greener tomorrow.