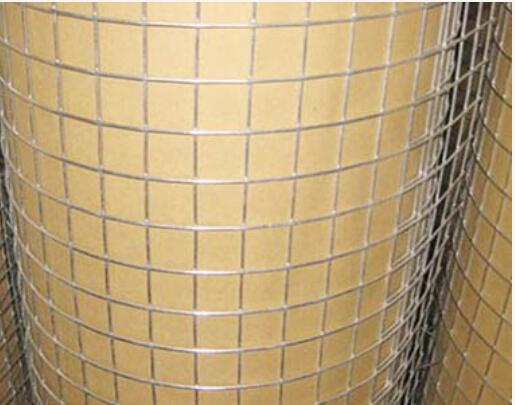

Welded wire mesh (left) and square wire mesh (right) serve distinct roles across industries — here’s how to choose the right one.

When Metal Meets Engineering: The Origins of Two Mesh Innovations

The evolution of wire mesh is a testament to human ingenuity meeting industrial demand. Welded wire mesh emerged as a solution for consistent, high-strength reinforcement in modern concrete structures. Created by electrically fusing intersecting wires at precise points, this method ensures uniform rigidity and dimensional accuracy. In contrast, square wire mesh traces its roots to traditional weaving techniques, where wires are interlaced to form a balanced grid. This flexible, yet durable structure found early use in filtration and fencing. While both originate from the need for reliable metal frameworks, their manufacturing paths diverge — one rooted in automation and precision, the other in adaptability and resilience.

The production process defines performance: welding creates rigid nodes, while weaving allows slight flexibility at intersections.

Anatomy of Strength: Understanding Structural Differences

At first glance, both meshes may appear similar, but a closer look reveals critical distinctions in their structural DNA. Welded wire mesh features fixed junctions where wires are fused under heat, resulting in a rigid, non-shifting lattice. This makes it ideal for applications requiring dimensional stability. Square wire mesh, however, relies on mechanical interlocking — each wire passes over and under its neighbor, allowing micro-movements that absorb stress without fracturing. Visually, welded mesh displays clean, symmetrical weld points, while square mesh shows a more organic, fabric-like texture. These differences directly influence load distribution: welded variants resist vertical pressure exceptionally well, whereas square mesh excels in dynamic environments where vibration or thermal expansion occurs.

In reinforced concrete slabs, welded wire mesh acts as an internal skeleton, preventing crack propagation and enhancing tensile strength.

Guardians of the Built Environment: Performance in Construction

In modern construction, welded wire mesh has become indispensable for reinforcing concrete floors, driveways, and foundations. Its ability to distribute loads evenly reduces cracking caused by shrinkage or external stress. When embedded during pouring, it forms a continuous network that significantly boosts structural integrity. Meanwhile, square wire mesh plays a supporting role in formwork systems and as separation layers between different materials. Its flexibility allows it to conform to curved surfaces or uneven substrates, making it perfect for complex architectural designs. Contractors appreciate its ease of handling and compatibility with insulation or drainage membranes.

Balancing Security and Visibility: Agricultural and Fencing Uses

Farmers and land managers face the constant challenge of securing livestock while maintaining airflow and visibility. Here, the choice between mesh types becomes strategic. Welded wire mesh, with its robust joints, is preferred for containing larger animals like cattle or pigs, where impact resistance is crucial. For poultry or smaller enclosures, square wire mesh offers finer control over aperture size and greater pliability during installation. Both benefit from galvanization or PVC coating, which protect against rust and extend service life in humid or corrosive environments. Real-world installations show treated meshes lasting over 15 years with minimal maintenance, even in coastal or high-rainfall regions.

From conveyor belts to protective guards, industrial applications rely on the durability and open-area consistency of precision-engineered wire mesh.

The Backbone of Industry: From Conveyors to Ventilation

Inside factories and processing plants, these meshes operate behind the scenes. Welded wire mesh dominates in high-wear areas such as conveyor belts and machine guards due to its resistance to deformation under continuous load. Its stable openings also make it suitable for elevated platforms and walkways. On the other hand, square wire mesh shines in screening and filtration systems, where consistent hole geometry ensures accurate particle separation. HVAC units and exhaust housings utilize its uniform airflow characteristics, improving energy efficiency and reducing clogging risks.

Speed, Simplicity, and Smart Installation

Time is money on any job site, and pre-fabricated welded mesh delivers speed through modular design. Panels arrive ready to lay, minimizing cutting and alignment work. Their standardized dimensions integrate seamlessly with rebar spacing protocols. Square wire mesh, often supplied in rolls, offers adaptability — it can be trimmed easily and shaped around obstacles. However, achieving tight connections may require additional fasteners. When rapid deployment is key, welded mesh typically wins; for custom-fit scenarios, square mesh provides unmatched versatility.

The True Cost of Ownership: Beyond the Price Tag

While welded mesh may carry a higher upfront cost, its longevity and reduced labor needs often lead to lower total expenditure over time. Fewer repairs and replacements mean less downtime and material waste. Square mesh, though initially cheaper per square meter, might require earlier intervention in high-stress zones. A lifecycle analysis conducted across infrastructure projects revealed that galvanized welded mesh delivered up to 30% savings over 20 years when factoring in maintenance and structural performance.

Sustainable Infrastructure: Recyclability and Eco-Design

Both mesh types are predominantly made from recyclable steel, aligning with green building standards like LEED. Manufacturers are increasingly using recycled content in production, reducing carbon footprints. Moreover, damaged sections can be removed and replaced without scrapping entire panels, promoting resource efficiency. As sustainable construction gains momentum, these attributes position wire mesh as a responsible choice for eco-conscious developers.

The Future is Flexible: Customization and Smart Integration

Today’s projects demand tailored solutions. Leading suppliers now offer customizable wire diameters, mesh sizes, and coatings — from epoxy to stainless steel blends. This shift enables specialized uses in chemical plants, marine environments, and seismic zones. Looking ahead, prototypes of welded mesh embedded with strain sensors are being tested for real-time structural health monitoring in bridges and tunnels. Similarly, advanced alloys are expanding square mesh capabilities into extreme temperatures and abrasive conditions.

Conclusion: Choosing the Right Mesh for Your Mission

Whether you're reinforcing a skyscraper foundation or enclosing a backyard chicken coop, understanding the strengths of welded and square wire mesh empowers smarter decisions. One offers unyielding strength and precision; the other brings flexibility and adaptability. By matching the material to the mission, you ensure safety, efficiency, and long-term value — proving that sometimes, the smallest components hold up the largest ambitions.