Welded Wire Mesh vs Square Wire Mesh: Applications, Benefits & Uses Explained

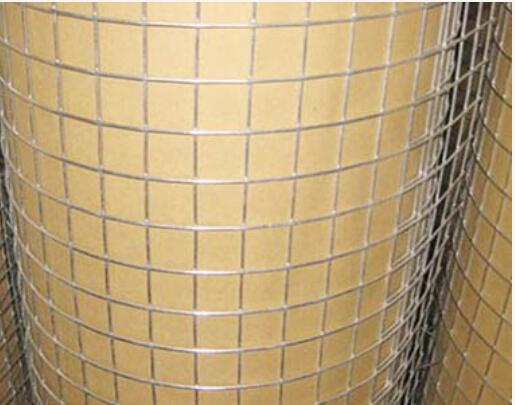

In the quiet hum of a construction site or along the edge of a rural pasture, metal mesh plays an unsung yet vital role in shaping our modern world. From towering skyscrapers to livestock enclosures, two types dominate the scene: welded wire mesh and square wire mesh. Though they may appear similar at first glance, their differences in manufacturing, strength, flexibility, and application reveal a deeper story of engineering precision and functional design.

When Metal Meets Structure: Decoding the Engineering Language of Wire Mesh

Every city skyline is held together by invisible reinforcements—among them, welded and square wire meshes silently bear loads, prevent cracks, and define boundaries. You’ll find welded mesh embedded within concrete slabs, ensuring structural integrity, while square wire mesh often forms fences, flooring grids, and protective barriers across farms and factories. These materials are not interchangeable by default; each excels where its unique properties align with real-world demands.

The Secret Dialogue of Manufacturing: The Power of Spot Welding vs. the Rhythm of Weaving

The journey of these meshes begins in very different ways. Welded wire mesh is born from precision automation. Wires are laid perpendicular and fused at every intersection using electric resistance welding. This creates rigid, uniform grids with exceptional dimensional accuracy—ideal for applications requiring strict tolerances, such as reinforced concrete panels or industrial shelving.

In contrast, square wire mesh, typically produced through weaving, maintains the natural ductility of the base metal. Interlaced without melting, the wires retain their flexibility, allowing the mesh to absorb dynamic stresses more effectively. This makes it particularly suitable for environments where vibration, thermal expansion, or uneven terrain could compromise a stiffer structure.

Bearing the Load: Real-World Structural Performance Compared

Imagine a high-rise building rising into the clouds. Its foundation and floor slabs rely heavily on welded wire mesh to control cracking under immense compressive forces. The rigidity and consistent node strength allow even distribution of stress throughout the concrete matrix, minimizing microfractures over time. In this context, dimensional stability isn’t just beneficial—it’s essential.

Now picture a poultry farm where animals move constantly across wet, slippery surfaces. Here, square wire mesh takes center stage. Installed as flooring, its open weave allows waste to pass through while providing secure footing. More importantly, its slight give underfoot reduces joint strain on animals and resists deformation under repeated impact—something a brittle welded grid might fail to handle over time.

More Than Just Fencing: Surprising Roles Across Industries

These meshes have evolved far beyond basic containment. Welded wire mesh now serves as protective cladding on bridges, scaffolding safety nets, and even architectural facades that blend strength with aesthetic appeal. Artists and designers use it creatively in sculptures and interior partitions, drawn to its clean lines and modularity.

Meanwhile, square wire mesh thrives in mechanical systems—used in vibrating screens for mining operations, ventilation grilles in HVAC units, and sound-dampening panels in urban infrastructure. Its ability to be formed into cylinders or curved shapes gives engineers freedom unmatched by rigid alternatives.

Durability Under Fire: Resistance to Rust, Impact, and Time

Longevity depends not only on material but also on surface treatment. Both meshes benefit from galvanization, which coats the steel in zinc to resist corrosion. However, because welded joints create localized heat zones during production, those points can be slightly more vulnerable to early rust if coating quality varies. PVC-coated versions enhance protection further, especially in coastal areas exposed to salt spray.

Square wire mesh, with no welds to weaken, often demonstrates superior fatigue resistance in fluctuating climates. Its continuous wires expand and contract uniformly, reducing the risk of crack propagation—a critical advantage in regions with extreme temperature swings.

The True Cost Equation: Balancing Upfront Price with Lifelong Value

While welded mesh may carry a higher initial price tag due to its automated fabrication, its rapid installation can slash labor costs significantly. On large-scale projects like highway paving or precast concrete manufacturing, this efficiency translates into faster timelines and lower overall expenditure. Some contractors report installations completed 40% faster compared to traditional rebar tying.

Square wire mesh, though sometimes cheaper per panel, may require additional framing or support when used in load-bearing roles. Yet in applications like animal housing or erosion control, its adaptability to irregular landscapes reduces the need for site modification—another hidden saving.

Making the Right Choice: Matching Material to Mission

There’s no universal winner. When precision, stiffness, and integration with automated systems matter most, welded wire mesh stands out. For projects demanding flexibility, resilience to movement, or custom shaping, square wire mesh offers unmatched versatility. Consider how easily each type can be cut, joined, or anchored on-site—factors that influence both safety and long-term performance.

The Future of Wire Mesh: Smart Integration and Sustainable Innovation

The next generation of wire mesh is already emerging. Researchers are embedding sensors into welded wire mesh to monitor structural health in real time—detecting stress points before failure occurs. Meanwhile, eco-conscious manufacturers are producing square wire mesh from up to 95% recycled steel, reducing carbon footprints without sacrificing strength.

As cities grow smarter and sustainability becomes non-negotiable, these humble grids are evolving into intelligent, green components of tomorrow’s infrastructure. Whether reinforcing a bridge or shielding sensitive equipment, their role continues to expand—proving that even the simplest designs can shape the future.