Welded Wire Mesh vs Square Wire Mesh: Applications, Benefits & Buying Guide

In the world of construction, agriculture, and industrial engineering, the choice between welded wire mesh and square wire mesh can define the success or failure of a project. These two materials, though seemingly similar at first glance, are shaped by different manufacturing philosophies, each offering unique advantages depending on the application. Whether you're reinforcing concrete, designing ventilation systems, or setting up a livestock enclosure, understanding the subtle engineering behind these wire forms can make all the difference.

Two Grids, Two Philosophies: The Structural DNA Behind the Mesh

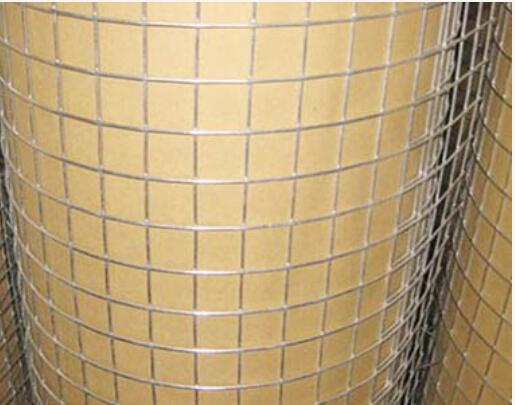

The fundamental difference between welded and square wire mesh lies in how they are constructed. Welded wire mesh is formed by fusing individual wires at their intersection points using resistance welding, creating a rigid and uniform structure. This process results in a strong, stable grid that maintains its shape under tension or pressure.

In contrast, square wire mesh is typically woven rather than welded. The wires are interlaced in a crisscross pattern, allowing for a degree of flexibility while maintaining a regular, geometric appearance. This weaving technique gives square mesh a more organic, textile-like quality that can be advantageous in applications requiring adaptability.

Industrial Battlefields: The Silent Guardians of Heavy-Duty Environments

In industrial environments where machinery vibrates, materials shift, and durability is paramount, welded wire mesh often takes center stage. Its rigid structure makes it ideal for use in conveyor belts, automated production lines, and heavy-duty fencing systems. The point-welded intersections ensure that the mesh remains intact even under constant stress, preventing deformation or failure.

Square wire mesh, on the other hand, thrives in applications where even distribution of force is more important than sheer rigidity. In screening systems, ventilation ducts, and filtration panels, its uniform weave allows for balanced airflow and material flow, making it a preferred choice in HVAC systems and industrial sieves.

Agricultural Agility: The Invisible Fencing of Farms and Fields

In agricultural settings, both types of mesh find their niche. Welded wire mesh is often used in fencing for livestock enclosures due to its strength and resistance to animal impact. The fixed intersections prevent animals from bending or breaking through the fence, ensuring long-term security.

Conversely, square wire mesh plays a more delicate role in farming operations. It’s commonly used in seed trays, nursery beds, and irrigation systems where precision and uniformity are essential. Its regular pattern allows for consistent spacing, aiding in seed distribution and water drainage, making it a staple in precision agriculture.

Architectural Expression: From Structural Support to Aesthetic Design

In the construction industry, welded wire mesh is frequently embedded in concrete slabs and walls to enhance tensile strength and prevent cracking. Its use in foundations, pavements, and retaining walls contributes to structural integrity, especially in seismic zones or areas prone to soil movement.

Meanwhile, square wire mesh has found a place in architectural design. Its clean, geometric pattern lends itself well to decorative partitions, façades, and sunscreens. Architects and designers appreciate its visual appeal and modularity, using it to create modern, breathable exteriors or stylish interior dividers.

Making the Right Choice: A Decision Map for Material Selection

Choosing between the two mesh types isn’t always straightforward. Factors such as load-bearing requirements, environmental exposure, and cost constraints play a crucial role. For applications requiring high structural integrity and minimal deformation, welded wire mesh is the better option. When flexibility, even distribution, or aesthetic design is a priority, square wire mesh may be more appropriate.

Cost-wise, welded mesh tends to be slightly more expensive due to the complexity of the welding process. However, its longevity and minimal maintenance requirements often justify the initial investment. Square mesh, being easier to produce, is generally more affordable and suitable for short-term or less demanding applications.

Hidden Advantages: Beyond Just Wire and Welds

While the physical structure of the mesh is important, there are other hidden qualities that should not be overlooked. For instance, both types can be coated with galvanized or PVC layers to enhance corrosion resistance, especially in outdoor or high-humidity environments. Additionally, the ability to weld or integrate into larger structures can affect installation time and labor costs.

Another often-overlooked factor is recyclability. Both welded and square wire mesh are made primarily from steel or stainless steel, which are highly recyclable materials. This makes them a sustainable choice in green construction and eco-conscious engineering projects.

Five Critical Questions Before You Buy

Before making a purchase, consider these five non-technical but essential questions:

- Will the mesh be exposed to sharp edges or frequent handling? Check for smooth edges and possible burrs.

- Is the mesh available in roll or flat sheets? This affects transportation and installation logistics.

- What is the acceptable tolerance range? Especially important for modular or prefabricated systems.

- How will the mesh interact with adjacent materials? Compatibility with coatings, adhesives, or fasteners is key.

- What is the expected lifespan of the application? This determines whether investing in higher-grade or coated mesh is worthwhile.

The Future of Mesh: Adapting to the Age of Smart Construction

As the construction and manufacturing industries embrace digital transformation, the role of wire mesh is also evolving. Smart mesh systems embedded with sensors are now being developed to monitor stress, temperature, and moisture in real-time. These innovations are paving the way for self-diagnosing infrastructure that can alert engineers to potential failures before they occur.

Moreover, advancements in 3D printing and modular construction are influencing mesh design. Newer forms of welded mesh with adaptive node structures are being tested for use in curved or complex geometries, expanding their applicability beyond traditional rectilinear designs.

Conclusion: Choosing the Right Mesh for Your Project

Ultimately, the choice between welded wire mesh and square wire mesh depends on the specific demands of your project. Each has its own set of strengths, and understanding those will help you make a more informed decision. Whether you're reinforcing concrete, designing a ventilation system, or creating an architectural feature, the right mesh can elevate your work from functional to exceptional.