In the world of construction and industrial materials, few products offer the perfect balance of strength and adaptability quite like welded wire mesh and square wire mesh. These two versatile materials have quietly become essential components in a wide range of applications—from towering skyscrapers to backyard chicken coops. In this article, we’ll take a deep dive into what makes these wire meshes so valuable, explore their unique properties, and discover how they shape the environments we live and work in.

Steel Craftsmanship: Why Wire Mesh Is the Secret Weapon of Modern Engineering

The story of wire mesh is one of innovation and endurance. From the intricate ironwork of ancient Rome to the mass-produced materials of the Industrial Age, wire mesh has evolved to meet the demands of modern engineering. Today, both welded and square wire mesh are used in everything from reinforcing concrete structures to supporting delicate plant growth in greenhouses. Their strength, durability, and malleability make them favorites among architects, engineers, and DIY enthusiasts alike.

What sets these materials apart is not just their structural integrity, but their ability to be customized for specific applications. Whether you need a rigid framework for a bridge or a flexible barrier for a garden fence, there’s a wire mesh solution that fits your needs perfectly.

Decoding Structural Beauty: The Core Differences Between Welded and Square Wire Mesh

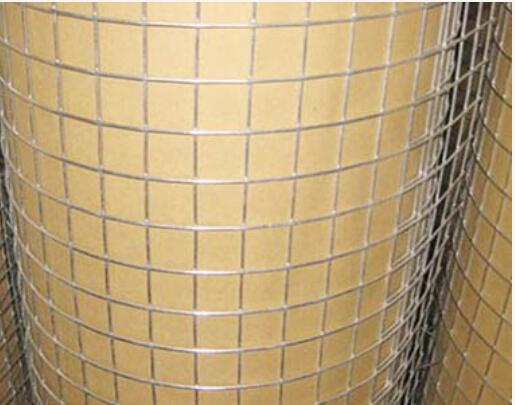

At first glance, welded wire mesh and square wire mesh may seem similar, but their construction methods and resulting properties are quite distinct. Welded wire mesh is created by fusing intersecting wires at their points of contact, forming a rigid and stable grid. This method ensures that the mesh holds its shape under pressure, making it ideal for applications that require structural support.

On the other hand, square wire mesh is typically woven rather than welded, allowing for more flexibility and easier manipulation. This makes it a preferred choice for projects that require bending or shaping, such as fencing or decorative installations. When comparing the two, consider the balance between load-bearing capacity and adaptability—welded mesh excels in static strength, while square mesh shines in dynamic applications.

The Invisible Guardian of Construction Sites: Supporting the Cities of Tomorrow

In modern infrastructure, welded wire mesh plays a crucial role in reinforcing concrete. By embedding it within slabs and walls, builders significantly enhance the tensile strength of the structure, reducing the risk of cracks and failures. This technique is commonly used in roads, bridges, and high-rise buildings where durability is non-negotiable.

Meanwhile, square wire mesh is often found in safety applications like fencing and protective barriers. Its ability to be easily cut and shaped makes it ideal for temporary or semi-permanent installations, such as construction site perimeters or animal enclosures. A real-world example of this synergy can be seen in large-scale infrastructure projects, where both types of mesh are used in tandem to provide both strength and adaptability.

From Farms to Factories: Versatility Across Industries

The utility of wire mesh extends far beyond construction. In agriculture, welded wire mesh is frequently used to build chicken coops, rabbit cages, and greenhouse supports. Its strength ensures the safety of animals and plants, while its resistance to rust and corrosion ensures long-term use.

In industrial settings, square wire mesh is employed in filtration systems, conveyor belts, and machine guards. Its open grid allows for airflow and visibility while still offering protection against debris and hazards. For creative minds, these materials also offer a unique medium for DIY projects—from custom furniture to large-scale art installations.

The Art of Selection: Choosing the Right Wire Mesh for Your Project

Choosing between welded and square wire mesh starts with understanding your project’s requirements. If you're reinforcing a concrete foundation, the rigidity and strength of welded mesh are your best bet. For fencing, animal enclosures, or curved structures, square mesh offers the flexibility you need.

Material selection is also critical. Galvanized wire offers excellent corrosion resistance, making it ideal for outdoor use. Stainless steel is preferred in environments where chemical exposure is a concern, while cold-drawn steel offers maximum strength for heavy-duty applications. Additionally, the thickness of the wire and the size of the mesh openings will influence both performance and cost.

The Future of Wire Mesh: Sustainability and Smart Integration

As the world shifts toward more sustainable building practices, wire mesh stands out for its recyclability and long lifespan. Both welded and square wire mesh can be reused or repurposed, reducing waste and environmental impact.

Looking ahead, new technologies are exploring ways to integrate smart features into wire mesh—such as embedded sensors for structural monitoring or energy-efficient coatings that improve thermal performance. With the development of advanced alloys and manufacturing techniques, the next generation of wire mesh promises to be even more durable, efficient, and adaptable.

Making the Right Choice: From Theory to Real-World Application

When deciding on the right wire mesh for your project, start by answering a few key questions: What kind of load will the mesh support? Will it be exposed to harsh weather or chemicals? Do you need flexibility or rigidity? Understanding these factors will guide you toward the most suitable option.

Avoid common pitfalls like choosing the cheapest option without considering durability, or selecting a mesh that's too rigid for the intended application. Consulting with a supplier or expert can help ensure that your choice aligns with both your functional and aesthetic goals.

Conclusion

Whether you're reinforcing a concrete slab, building a secure enclosure, or crafting a custom design, welded wire mesh and square wire mesh offer a perfect blend of strength and flexibility. Their wide range of applications, combined with their adaptability and sustainability, make them indispensable tools in modern engineering and design. By understanding their unique properties and uses, you can make an informed decision that ensures the success of your next project.