From towering industrial complexes to serene backyard gardens, welded wire mesh and square wire mesh have become indispensable elements across a wide range of applications. These seemingly simple materials are not only robust and durable but also incredibly adaptable, offering both structural integrity and aesthetic appeal. Whether you're a construction manager, a creative designer, or a DIY enthusiast, there’s a mesh solution tailored to meet your needs.

Structural Beauty Across Scenarios: From Factory to Garden

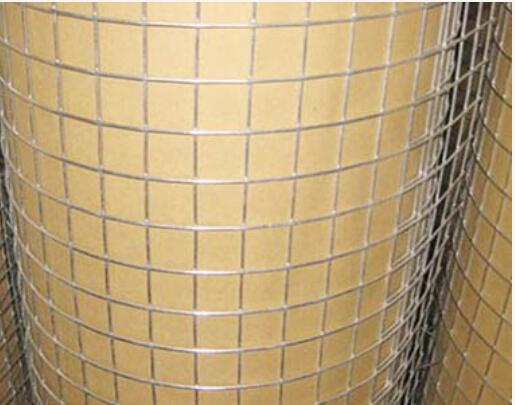

Welded wire mesh and square wire mesh demonstrate their strength and adaptability in environments as diverse as manufacturing plants and flowerbeds. In industrial settings, these materials serve as essential components for equipment guards, partitioning systems, and even flooring grids. Their uniform structure and high tensile strength make them ideal for supporting heavy loads and ensuring safety in high-traffic areas.

In contrast, the same materials find a more delicate purpose in gardens and outdoor spaces. Square wire mesh, for instance, is often used to create trellises that support climbing plants, while welded wire mesh can be fashioned into lightweight fencing that enhances garden aesthetics without compromising security. The variety of available thicknesses and hole sizes allows for precise customization, ensuring that each application meets both functional and visual requirements.

The Designer's Secret Weapon: How Metal Mesh Sparks Creative Inspiration

Beyond their utilitarian uses, welded and square wire mesh have become favored materials among architects and interior designers. The unique texture and geometric patterns of metal mesh add a modern, industrial touch to any space. Whether used for ceiling dividers, wall art, or custom furniture, these materials offer a dynamic interplay between light and shadow, creating depth and interest in both residential and commercial interiors.

To enhance their visual appeal and longevity, many mesh products undergo surface treatments such as galvanization or powder coating. Galvanized mesh resists corrosion and maintains its structural integrity even in humid or outdoor conditions, while powder-coated versions offer a splash of color and a smoother finish. These enhancements not only protect the mesh from wear and tear but also allow for greater design flexibility.

The Silent Guardian in Agriculture and Livestock: Creating Safe and Efficient Environments

In agricultural and livestock operations, the durability and adaptability of square wire mesh make it a go-to choice for enclosures, poultry coops, and animal pens. Its precise openings allow for proper ventilation while preventing escapes and keeping predators out. Welded wire mesh, on the other hand, is often used to construct greenhouse frames, feed storage bins, and partition walls, offering both strength and ease of assembly.

Choosing the right mesh for agricultural use involves considering factors like corrosion resistance, wire thickness, and environmental exposure. Meshes with PVC coatings or hot-dipped galvanization are especially well-suited for outdoor use, as they can withstand harsh weather conditions and resist rust over time. These features ensure long-term performance and reduce the need for frequent replacements.

The Unsung Hero of Industrial Sites: Ensuring Safety and Efficiency

On construction sites and in warehouses, welded wire mesh plays a critical role in maintaining safety and organization. It is commonly used to create secure storage areas, protective barriers around machinery, and scaffolding components. The uniform welds and consistent spacing of the mesh ensure that it can withstand heavy impacts and support substantial weight without deforming.

When selecting mesh for industrial applications, it's important to compare specifications such as wire diameter, mesh size, and tensile strength. Different grades of mesh perform better under specific conditions—some are ideal for high-stress environments, while others prioritize flexibility and ease of installation. Additionally, welded mesh contributes to passive fire protection, seismic resilience, and improved airflow in large facilities.

DIY & Creative Living: Clever Ways to Use Metal Mesh at Home

For the home DIY enthusiast, welded wire mesh opens up a world of creative possibilities. From pet enclosures and garden planters to custom shelving and tool organizers, the material is both versatile and easy to work with. Its modular design allows for simple cutting and shaping, making it an ideal choice for weekend projects.

For example, repurposing mesh panels into vertical gardens or balcony railings can transform an ordinary space into a vibrant, functional area. With the right tools and a bit of ingenuity, even beginners can create stylish and durable solutions that blend practicality with personal flair.

The Art of Material Selection: Choosing the Right Mesh for Your Needs

Selecting the appropriate welded or square wire mesh involves more than just picking a size and shape. Key considerations include aperture size, wire thickness, material type (such as steel, stainless steel, or aluminum), and surface finish. Each of these factors influences the mesh’s performance, lifespan, and suitability for a given application.

For instance, a fine mesh with small openings might be used for security screens or filtration systems, while a coarser mesh with larger gaps could be better suited for agricultural fencing or industrial sieving. Understanding the interplay between these variables allows for smarter, more cost-effective choices that balance durability with affordability.

Looking Ahead: The Future of Metal Mesh in Green Building and Smart Agriculture

As sustainability becomes a driving force in modern design and agriculture, welded and square wire mesh are evolving to meet new demands. In green building, these materials are being integrated into eco-friendly facades, ventilation systems, and modular construction frameworks. Their recyclability and minimal environmental footprint make them ideal for projects focused on reducing carbon emissions and resource consumption.

In the agricultural sector, the rise of smart farming technologies has led to the development of mesh-based systems for automated feeding, climate control, and crop monitoring. By combining traditional materials with cutting-edge innovation, welded and square wire mesh are paving the way for more efficient, scalable, and environmentally responsible solutions.