While often overlooked, wire mesh plays a crucial role in shaping the modern world. Whether hidden beneath layers of concrete or standing proudly as a design feature, welded wire mesh and square wire mesh silently support structures, systems, and solutions across a wide range of industries. Their importance may not always be in the spotlight, but their impact is undeniable. Let’s explore the many ways these materials contribute to strength, function, and innovation.

Why Welded Wire Mesh Stands Out in Strength and Stability

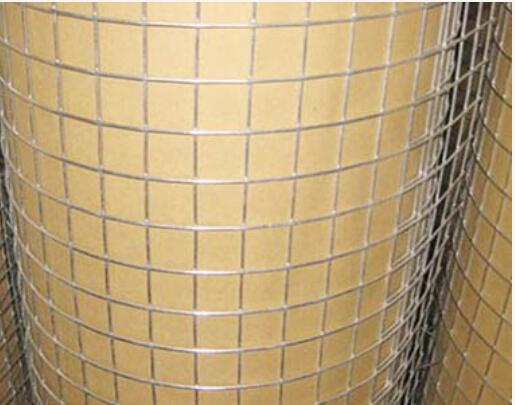

At the heart of many durable structures lies the unmatched strength of welded wire mesh. Unlike traditional woven wire, this type of mesh features wires that are precisely welded at every intersection, creating a rigid and stable framework. This process significantly enhances the material’s load-bearing capabilities, making it an ideal choice for reinforcing concrete in everything from residential driveways to massive infrastructure projects.

Its strength is not just theoretical—it's practical. In fencing applications, for instance, welded wire mesh offers superior resistance to impact and wear, ensuring long-lasting performance in demanding environments. From industrial flooring to security enclosures, its ability to withstand stress without compromising integrity makes it a go-to solution for engineers and builders alike.

Square Wire Mesh: The Perfect Blend of Form and Function

When precision and symmetry matter most, square wire mesh rises to the occasion. Known for its evenly spaced openings and clean lines, this type of mesh offers a balance between aesthetics and utility. Its uniform grid makes it ideal for applications where visual appeal is just as important as structural integrity—think decorative partitions, custom lighting fixtures, or even fine filtration systems in industrial settings.

In architecture, square wire mesh can be used to create dynamic facades that allow for airflow while maintaining privacy and style. Its adaptability also shines in manufacturing, where it supports processes requiring consistent mesh patterns for sifting, filtering, or screening. Whether used for beauty or utility, square wire mesh delivers a refined solution that meets both functional and design needs.

Industrial Marvels: How Wire Mesh Powers Manufacturing and Engineering

From the factory floor to the heart of complex machinery, wire mesh is a silent workhorse in industrial environments. Both welded and square wire mesh play pivotal roles in conveyor systems, where durability and consistent performance are essential. They also serve as protective guards for equipment, ensuring safe operation while allowing for ventilation and visibility.

Engineers rely on these materials to craft components that are both strong and lightweight, contributing to innovations in everything from automotive manufacturing to aerospace engineering. Their ability to withstand high temperatures and resist wear makes them indispensable in environments where reliability is non-negotiable.

From Farm to Fence: Agricultural Applications That Rely on Wire Mesh

In agriculture, wire mesh is a versatile ally. Farmers use it for everything from constructing secure enclosures for livestock to creating trellises that support climbing crops. Welded wire mesh, with its high tensile strength, is often used for fencing that needs to withstand animal pressure and environmental wear, while square wire mesh excels in lighter applications like poultry netting or seedbed support.

These materials also play a role in protecting crops from pests and weather, making them a cost-effective solution for sustainable farming. Their durability in outdoor conditions ensures that agricultural operations can rely on them season after season.

Home is Where the Mesh Is: Residential Uses You Never Knew Existed

Homeowners may not always realize it, but wire mesh offers a host of creative and practical applications around the house. From DIY garden trellises to custom-built furniture pieces, it provides a lightweight yet sturdy material that’s easy to shape and adapt. Security-conscious individuals also turn to welded wire mesh to reinforce windows and doors without sacrificing visibility or natural light.

In interior design, square wire mesh can be transformed into stylish room dividers, lampshades, or wall art. Its modern look and industrial charm are increasingly popular in urban and minimalist aesthetics, proving that wire mesh is not just functional—it can be fashionable too.

Weathering the Storm: Longevity and Corrosion Resistance in Tough Conditions

One of the standout features of high-quality wire mesh is its ability to endure harsh conditions. Many types are galvanized or coated with protective layers that prevent rust and corrosion, ensuring long-term performance even in humid or coastal environments. This makes them ideal for outdoor installations, agricultural use, and marine applications.

Whether it’s welded or square mesh, selecting the right finish—such as PVC coating or stainless steel composition—can dramatically extend the lifespan of the material. Regular maintenance, such as cleaning and inspecting for wear, also helps preserve its structural integrity over time.

Beyond the Basics: Innovations and Emerging Uses in Wire Mesh Technology

As technology advances, so too does the potential of wire mesh. Innovations like smart fencing systems that integrate sensors and connectivity are redefining security and monitoring. Eco-friendly construction methods are also embracing wire mesh as a sustainable alternative, using it in green roofs, permeable pavement systems, and energy-efficient building designs.

Designers and engineers are experimenting with mesh patterns that enhance airflow, reduce material usage, and improve acoustic performance. These developments are pushing the boundaries of what wire mesh can do, proving that this seemingly simple material has a future full of exciting possibilities.

Choosing the Right Mesh for the Job: A Practical Guide

Understanding the differences between welded and square wire mesh is key to selecting the right product for your project. Welded mesh offers superior strength and rigidity, making it ideal for heavy-duty applications. Square mesh, with its uniform openings, is preferred for precision tasks and aesthetic uses.

When sourcing wire mesh, consider factors like wire diameter, mesh size, material type (such as galvanized steel or stainless steel), and finish. Working with a reputable supplier who can provide detailed specifications and samples ensures that you get a product that meets both performance and budgetary needs.

Building a Better Future – One Mesh at a Time

From towering skyscrapers to backyard gardens, wire mesh continues to shape the way we build, grow, and protect. Its versatility, durability, and adaptability make it a foundational element in countless applications. Whether you're a professional builder, a farmer, or a DIY enthusiast, choosing the right mesh can make all the difference in achieving a successful, long-lasting result.

As we look ahead, the potential of welded wire mesh and square wire mesh only continues to grow. By understanding their unique benefits and exploring new ways to apply them, we can unlock smarter, more sustainable solutions for the challenges of tomorrow. So next time you see a structure, a fence, or even a stylish design feature, remember—there’s a good chance wire mesh is quietly doing its part to make it stronger, safer, and more beautiful.